Our Services

Tube End Forming

We utilise the latest technology to offer a wide variety of industry standard tube end profiles and sizes. Our range of different types of Tube End Formers including ram or punch formers, Roll Formers, and Finger Expanders enables us to produce expanded and reduced tube ends, Single and double Flares for brake lines and hydraulic joints such as JIC, and ORFS.

We can also create beads for hose connection in fluid carrying systems, and formed tube ends for exhausts. We also have the ability to develop tooling and work with our customers should they have specific requirements.

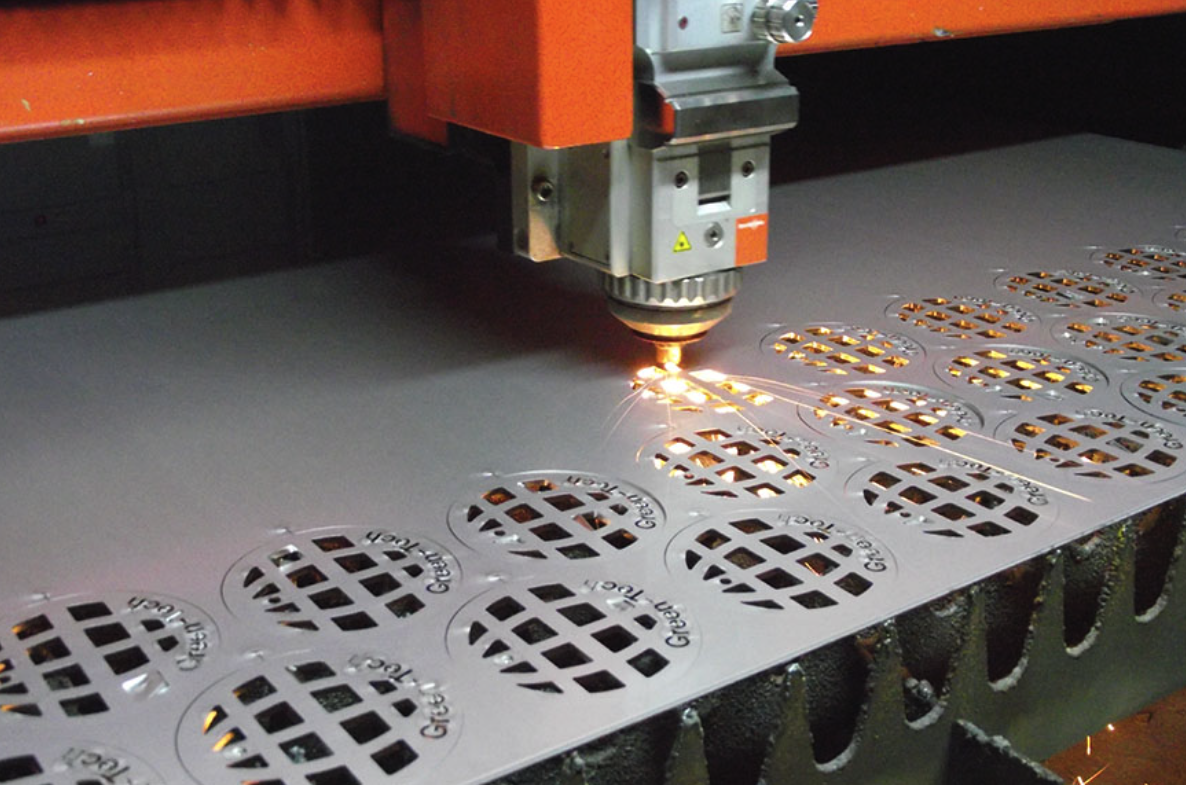

Laser Cutting/Profiling

In 2008 we made our first investment into Laser Profiling to improve our overall business efficiency supporting existing customers and introduce additional services to our business.

Recent investment in the latest Fibre Laser cutting technology with auto sheet feeder we are now able to efficiently process Mild Steel to 20mm, Stainless Steel to 15mm, Aluminium to 10mm Brass to 8mm & Copper to 6mm.

Sheet Bending/Folding

We are able to offer a variety of different metal folding solutions both manual and CNC which allows us to select the most appropriate method to meet the individual needs of our customers.

Our extensive range of multi axis CNC forming machines incorporate the latest press brake technology. They enable us to form complex parts with a capacity of 100T up to 3 metres accurately and consistently.

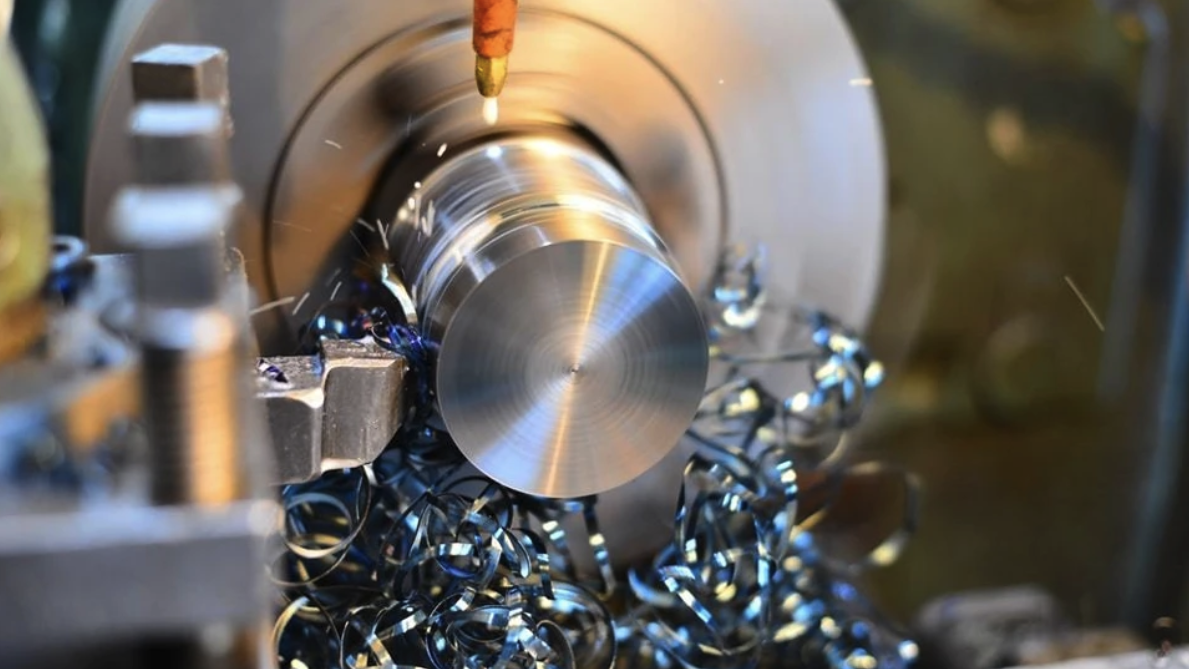

Machining

Technical Tubes has a wide range of Machining capability offering bespoke solutions to meet our customers manufacturing needs.

Our CNC milling capabilities operate across multiple axis, enabling us to produce complex engineered components at low and high volumes. Our dedicated team of engineers ensure your high precision components are manufactured quickly and accurately.

Turned components are produce to the highest quality guaranteeing precision and repeatability every time. Working closely with our trusted suppliers our streamlined process always meets the goals of your project.

Fabrication

Welding

To cater to different welding needs, we offer both MIG (Metal Inert Gas) welding and TIG (Tungsten Inert Gas) welding services. Meaning we can accommodate different requirements and ensure the best welding method is employed for each project.

Brazing

Whether small or large in volume our brazing services work for a number of organisations working in a variety of industries. We only use the highest quality raw materials and consumables to guarantee optimum joint strength and reliability for your product. Our processes include Induction heating for silver soldering, and torched brazing applications which include Bronze Welding for smaller batches and specific requirements.

Metal Polishing

For many years we have been able to offer a range of metal polishing finishes using a three station in-line polishing machine, electric pedestal and a range of hand polishing equipment. We offer a wide range of satin grains up to a bright mirror finish for Stainless Steel products.

We also polish to a pre-chrome standard on mild steel.

Tube Bending

Over time we have invested in a range of Tube Bending processes including CNC Mandrel bending, Compression Bending, Twin Head benders, and roll formers which allows us to offer a full bending service for tube and section profiles include Round, Box, and Flat Sided Oval ranging 4mm outside diameter up to 50mm (2”). Highly complex bending solutions can be achieved with our state of the art multi axis CNC bending machines.

We have the capability to manipulate various types of metals including mild steels, stainless steels, aluminium, copper, and brass.

Product Finishing and Treatments

Working in conjunction with our trusted and longstanding sub-contractors who we have built close relations with over many years we are able to off a range of finishes, these include Zinc Plating, Powder and wet Painting, and anodizing.

We also have our own in-house metal polishing department and can offer both dull and bright polished finishes on Stainless Steel products.